Factory "Soft roof" (Myagkaya Krovlya) is one of the the leading manufacturers of rolled roofing and waterproof materials.

Factory "Soft Roof " (Myagkaya Krovlya) is one of those few enterprises that managed to preserve its independence from large competitive corporations and its self-sustainable activities. We quickly respond to the needs and resource of our customers, take independent decisions about our working procedure, being guided only by the actual information and the coditions of the market of roofing materials.

Products by the Factory "Soft Roof " (Myagkaya Krovlya) have been widely used in the field of industrial and civil construction. The enterprise produces both standard roofing materials on a cardboard foundation ruberoid RKP-350, RKK-400, rubemast, bitumen paper, roofing paper), as well as up-to-date roofing materials. One of those materials is Armokrov® (reinforced roof), a modern polymer-bitumen synthetic based - roofing material. The analogs of Armokrov are such materials as Uniflex, Bikroelast, Elastoizol, Stekloelast, Linocrom, Bikrost, Fiberglass, Hydroisol.

The utstanding operational properties of Armokrov have been highly appreciated by the customers, therefore it´s worth saying that Armokrov is the best selling article among the roofing and waterproof materials.

CJSC "Soft Roof" (Myagkaya Krovlya) has been producing roofing cardboard, box board, flat container pasted boerd, packaging paper, bitumen-rubber mastic, bituminous primer, road bitumen, roofing (hot) mastic, road tar (hot) mastic for construction, oil bitumen for construction.

Factory "Soft Roof" (Myagkaya Krovlya) has repeatedly won first prizes in the contract tenders, conducted by the Federal Agency for State Reserves (Rosrezerv), in particular:

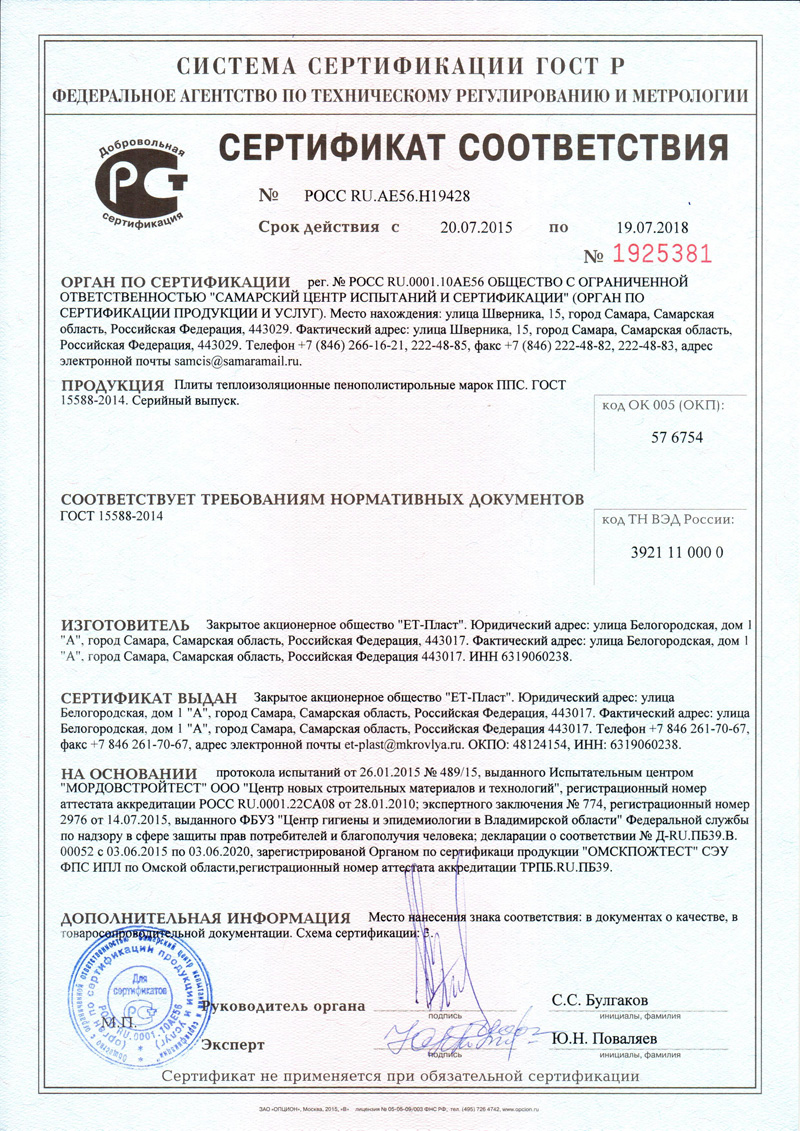

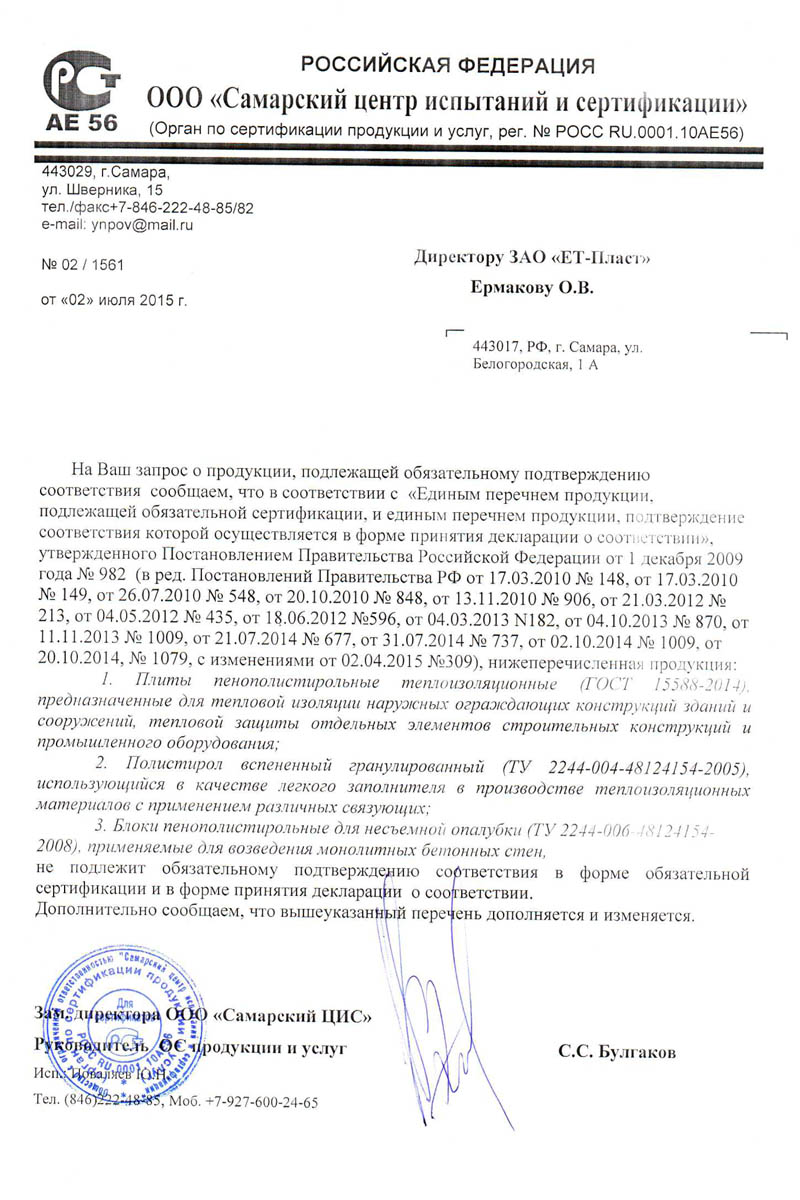

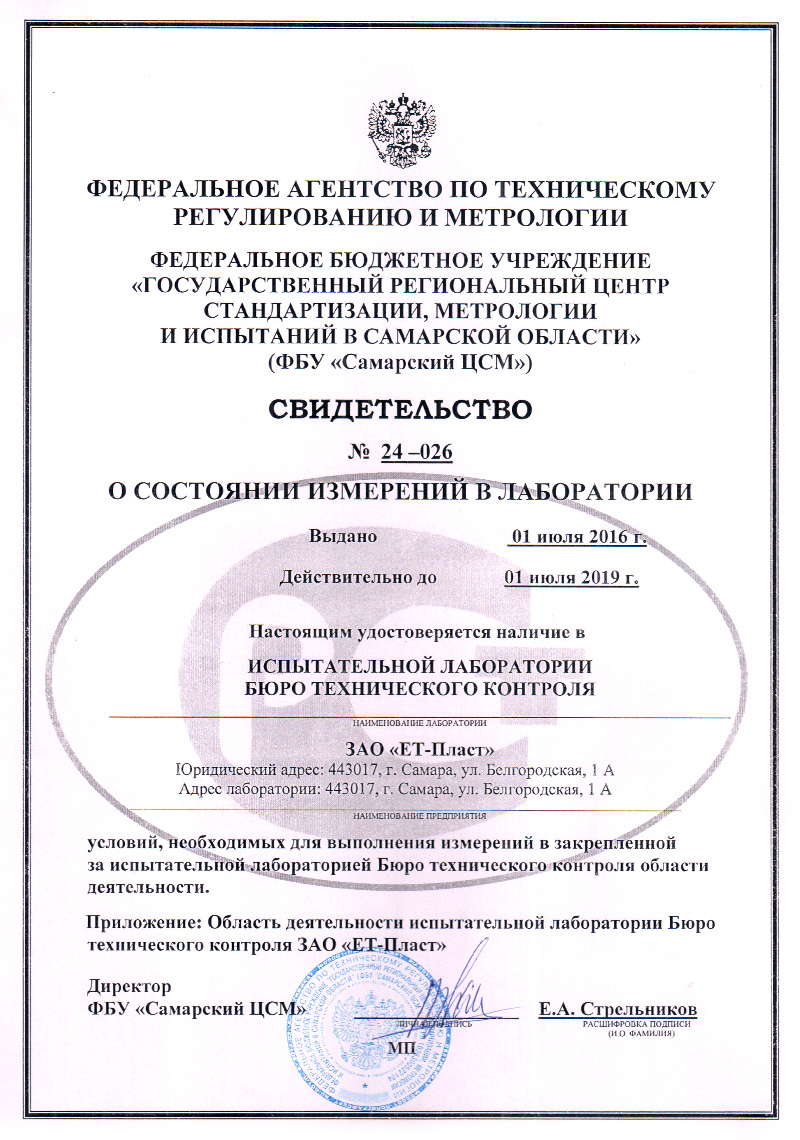

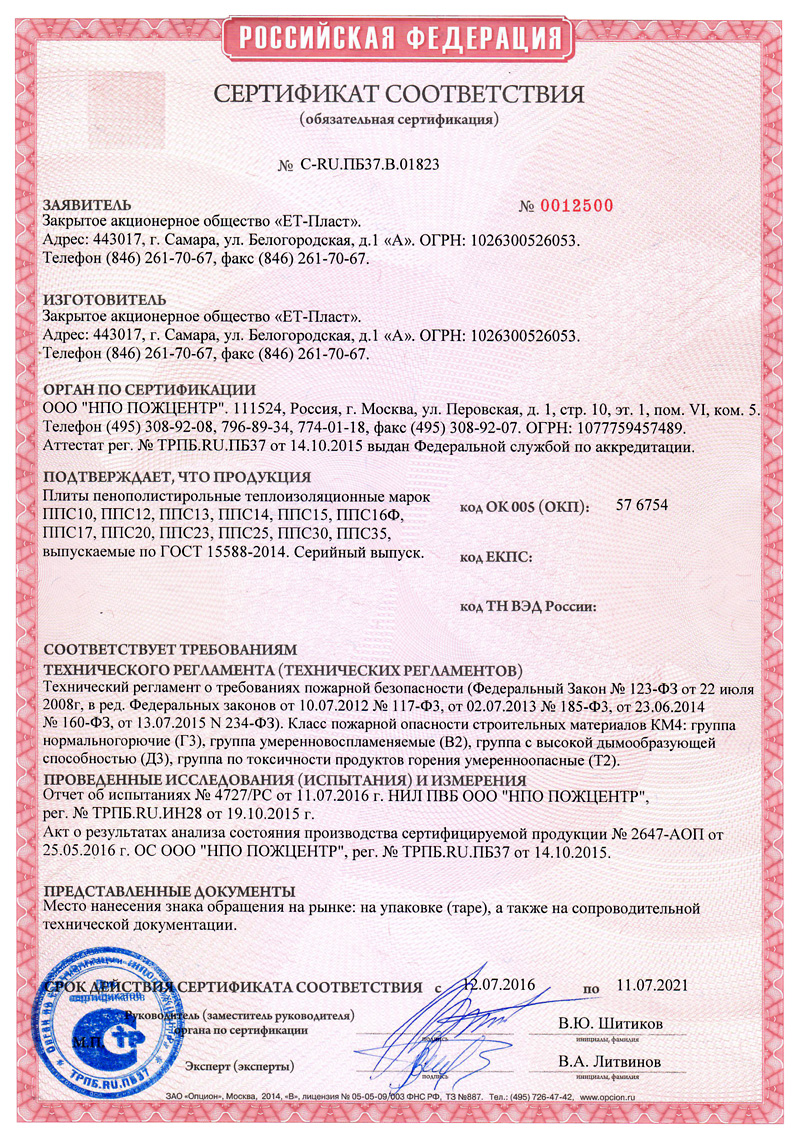

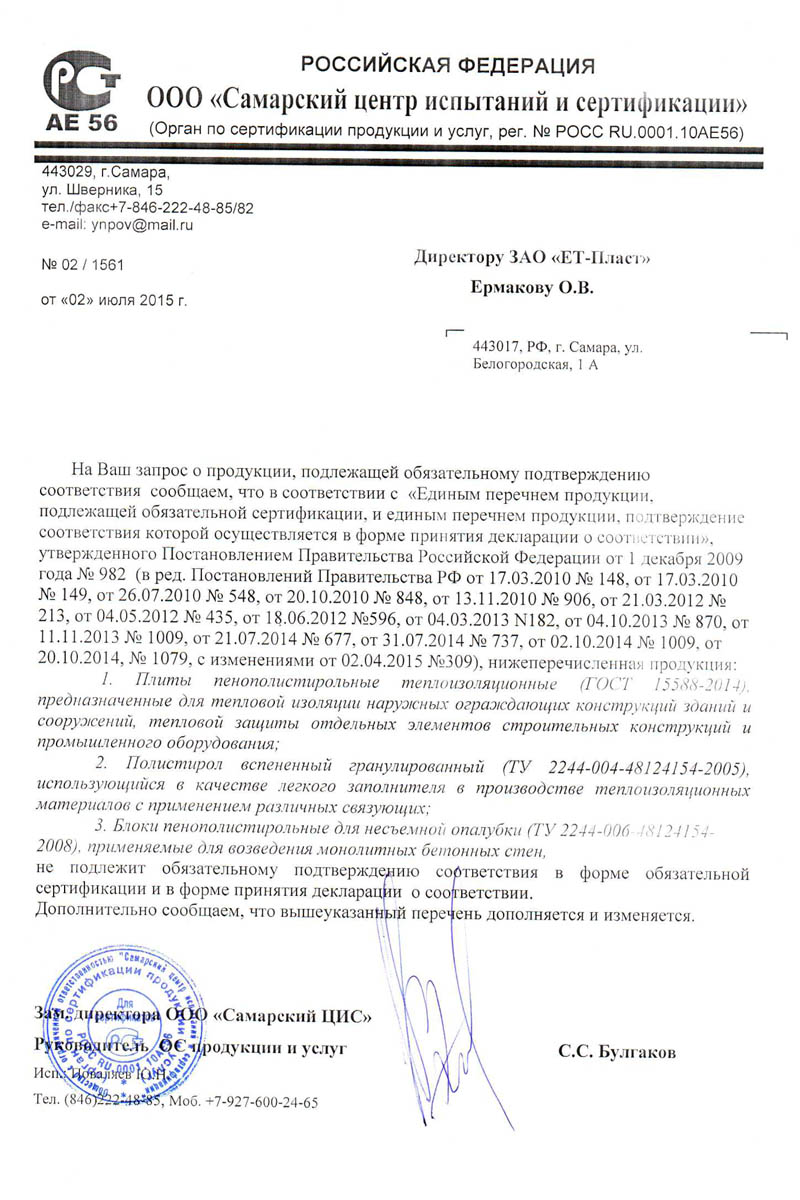

CJSC "ET-Plast" was founded in May, 2003 on the basis of CJSC "Soft Roof" (Myagkaya Krovlya) for manufacturing the new products - polystyrene slabs FPS. The polystyrene slabs produced by JSC "ET-Plast" present one of the most cost-effective materials, having high load resistance, low thermal conductivity, absolute resistance to biological and weather impact.

The Company "ET-Plast" has been producing bulk-polymerized self-extinguishing foam polystyrene upon the up-to-date automated line by HIRSCH Company (Italy).

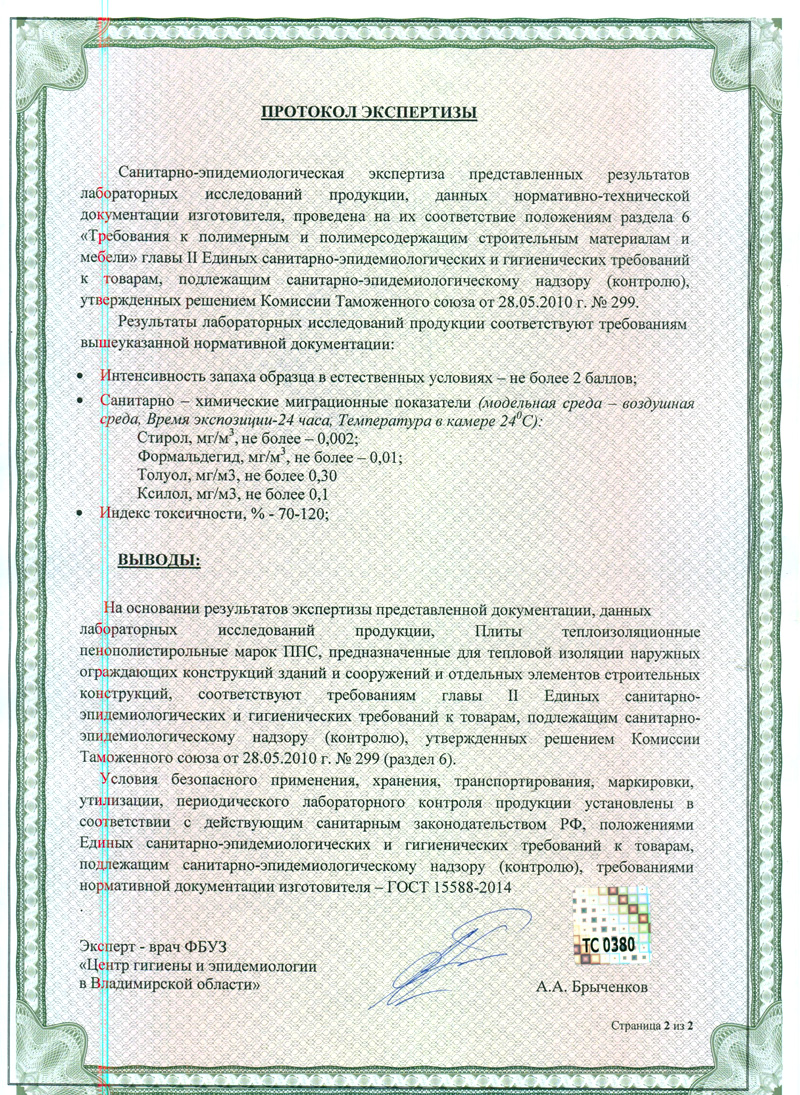

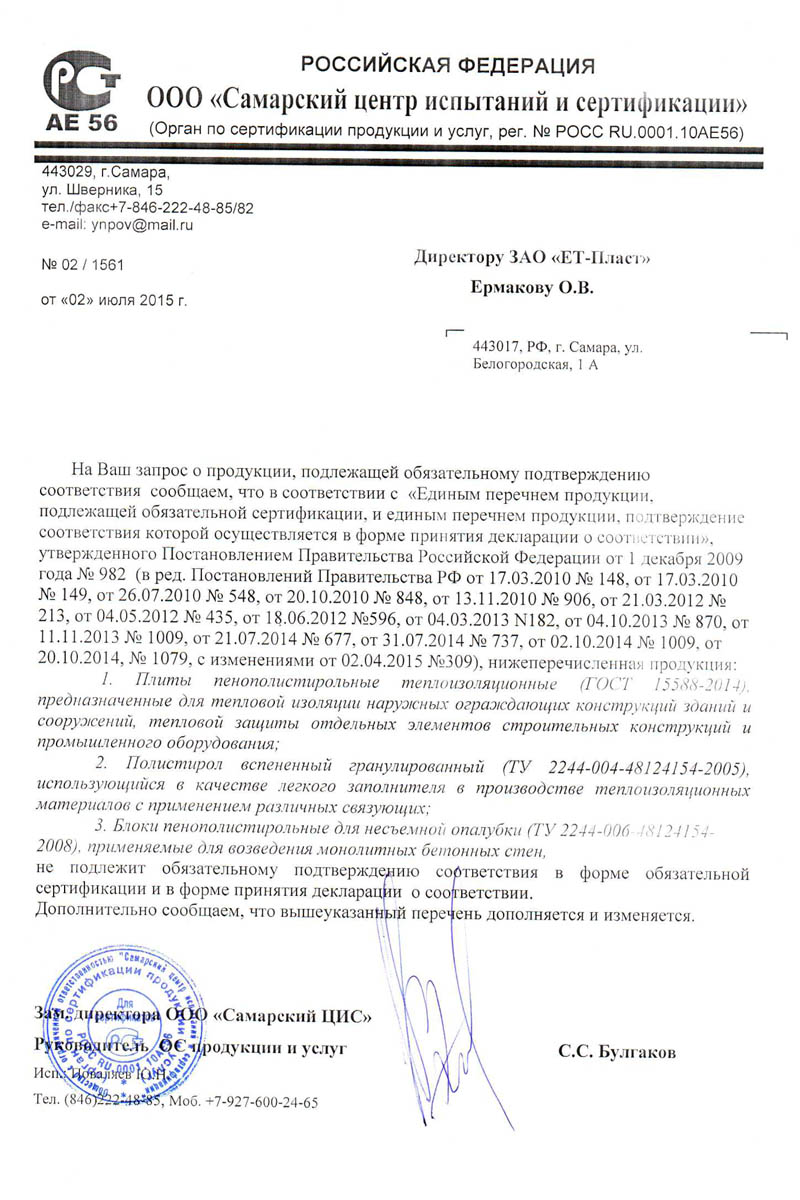

The slabs of foam polystyrene ППС by CJSC "ET-Plast" have been produced in accordance with the GOST 15588-2014, the quality of products is not inferior of their foreign analogues. The factory offers the manufacturing of slabs according to the customer´s dimensions.

CJSC "ET-Plast" has been also producing the stay-in-place formwork, granulated foam polystyrene, thermal containers, protective packaging, inserts for concrete blocks.

Our production company is one of the leaders in the Russian market of waterproof and heat-insulating materials, cardboard and paper, being a reliable supplier of those products upon the territory of Russian Federation and CIS countries within the recent decades. Thanks to the wide range of our products, perfect quality of our construction materials and a reasonable pricing policy, we have won recognition and appreciation from the thousands of customers!

We are interested in finding some new business partners and dealers, and we are ready to offer them the exclusive delivery terms and special spicing policy.

All the manufacured products are made of high-quality raw materials with the up-to-date equipment, in compliance of the process technology, followed by the strict quality control. Many dealers and construction companies from Samara, as well as from the regional enterprises and CIS countries, trust the quality of our finished goods. Our products are highly appreciated upon the Russian and foreign markets for its high quality, unique properties and long service life. We make as much effort as we can in order to provide the comfortsble service to our customers, therefore we pay much attention to apply the personal approach while working with our partners.

The reason is that cooperation with the dealers and construction companies is the key priority for us. If nowadays you work with some supplier and you are not satisfied with the quality of materials, prices or terms of delivery, you are tired of making excuses to your customes either for the low-quality goods or moving the installation date all the time, it means that you really need to change the manufacturer a.s.a.p. Working with the Factory "Soft Roof" (Myagkaya Krovlya), you will always have guarantee for the quality, manufacturing period and delivery terms of the required materials.

In case you continue to work with some supplier and you are satisfied with all the options, we still ask you to make consideration about our Company. Perhaps, we can offer you more favorable conditions, or become your "back-up" supplier for the roofing and heat-insulating materials, cardboard and paper, and we will always provide you with high quality products within a certain period of time at reasonable price and at the right time.

Having made you decision to cooperate with us, you'lle be offered the following advantages:

We offer our customers dozens of articles for the building rolled roofing, waterproof and heat insulation materials produced by our factory.

Options of reducing the price related to the increased volumes

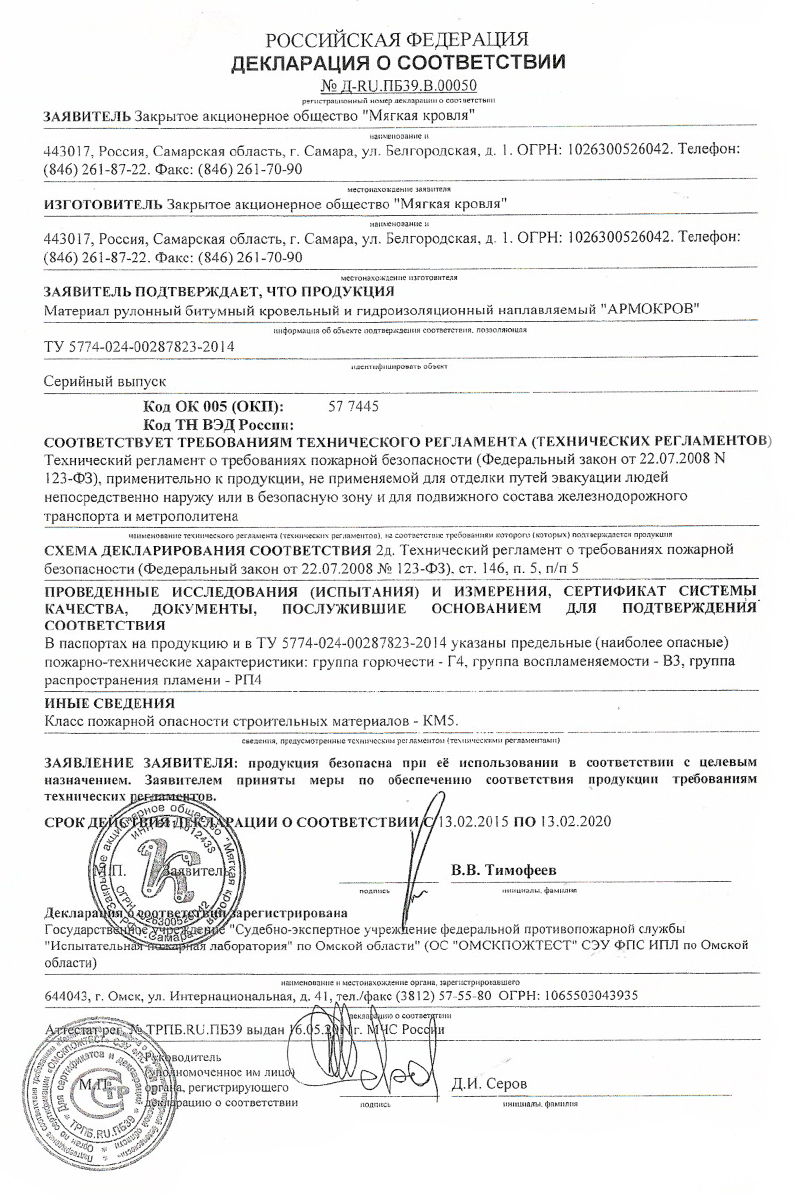

CooperationArmokrov is an up-to-date melting rolled bitumen-polymer roofing and waterproof material; the area of application is the construction of a roofing carpet of buildings and facilities for various purposes and construction of the waterproof foundations, bridges, and tunnels. Armokrov consists of a rot-proof base (polyester, fiberglass, glass cloth, combined fabric), coated with binding bitumen-polymer on both sides. Material complies with Technical Specifications 5774-024-00287823-2014.

The designations of the articles mean the type of the base: E means non-woven polyester fabric (polyester), X means glass cloth, T means fiberglass; and the related type of coating: P means protective polymer film, K means application of large mineral surface dressing.

Range of manufactured articles:

EKP-5.0, EPP-4.0

Range of manufactured articles:

EKP-4.5, EPP-3.5, TKP-4.5, TKP-4.0, TPP-3.5, TPP-3.0, XKP-4.0, XPP-3.0

Range of manufactured articles:

TKP-3.7, TPP-3.0, XKP-3.7, XPP-3.0

Range of manufactured articles:

TKP-3.7, TPP-2.5, TPP-2.2, XPP-2.5, XPP-1.9

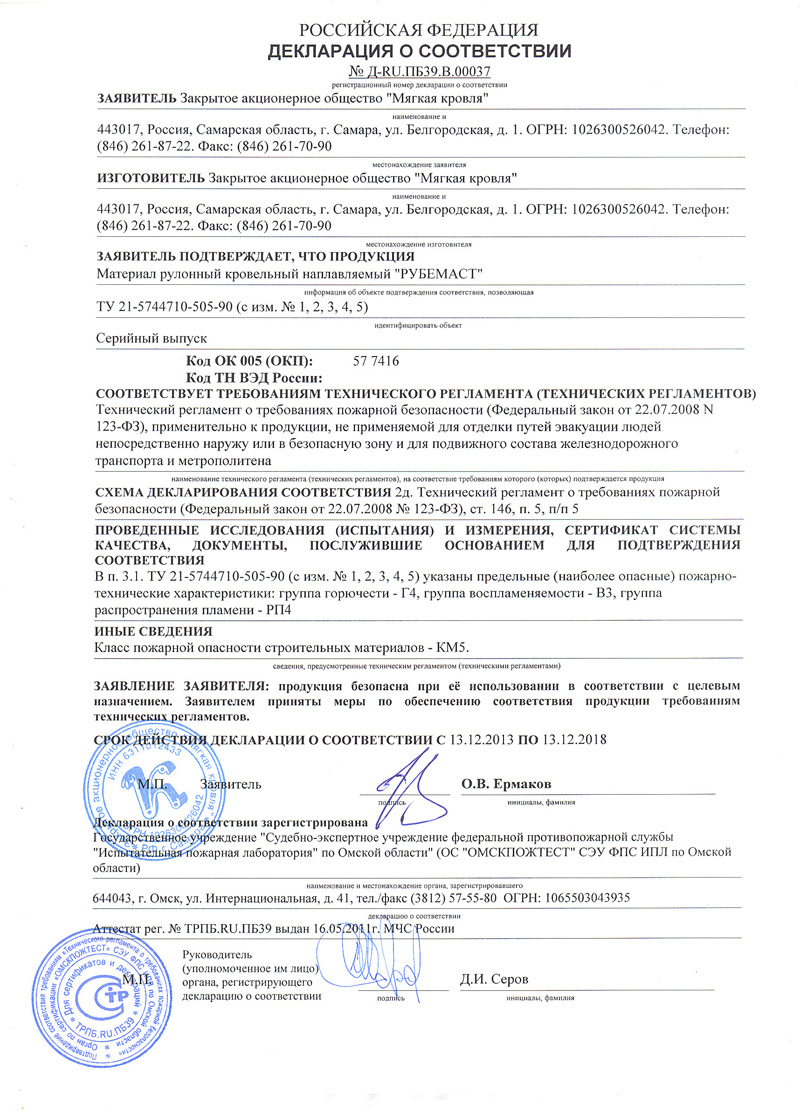

It’s the melting bituminous-based rolled roofing material with coarse-grained coating upon its front side and polyethylene film upon the underside of the cloth. It’s applied to form the upper layer of the roofing carpet.

It’s the melting bituminous-based rolled roofing material with polyethylene film on both sides of the cloth. It’s applied to form the upper layer of the roofing carpet with a protective layer and the lower layer of the roofing carpet.

It’s roofing ruberoid with coarse-grained coating. It’s applied to form the upper layer of the roofing carpet. The coarse-grained coating provides protection for the roofing material from exposure to sunlight and, as a result, helps prolong the service life of the roof. Material complies with GOST 10923-93.

It’s roofing ruberoid with dusty coating. It’s applied to form the upper layer of the roofing carpet with a protective layer, the lower layers of the roofing carpet and the waterproofing of building facilities. Material complies with GOST 10923-93.

It’s roofing ruberoid with dusty coating. It’s applied to form the upper layer of the roofing carpet with a protective layer, the lower layers of the roofing carpet and the waterproofing of building facilities. Material complies with Technical Specifications 5774-006-00287823-2003.

It’s roofing ruberoid with dusty coating. It’s applied to form the lower layer of the roofing carpet. Material complies with Technical Specifications 5774-006-00287823-2003.

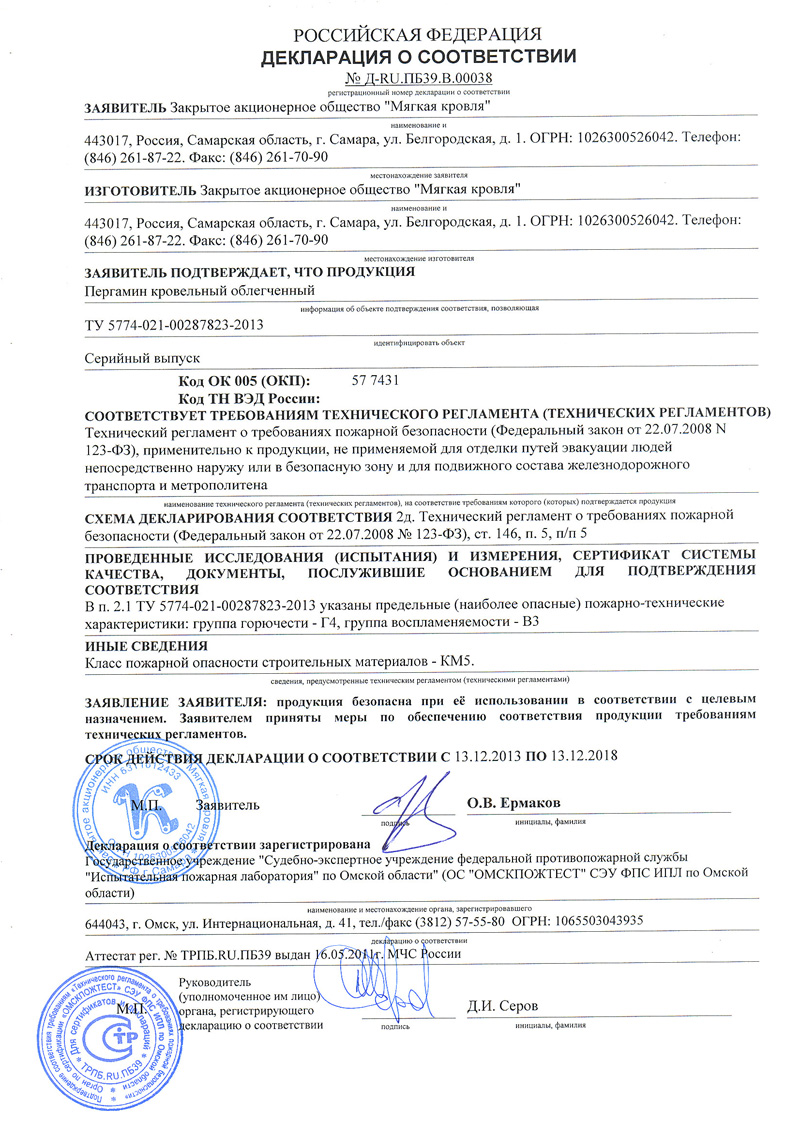

It’s the uncovered rolled material, made by means of impregnating the roofing paper (article 350) with oil bitumen. It’s the lining material. It’s applied to form the lower layers of the roofing carpet. Material complies with GOST 2697-83.

It’s the uncovered rolled material, made by means of impregnating the roofing paper (article 350) with oil bitumen. It’s the lining material. It’s applied to form the lower layers of the roofing carpet. Material complies with Technical Specifications 5774-021-00287823-2013.

It’s the uncovered rolled material, made by means of impregnating the roofing paper (article 350) with oil bitumen. It’s the lining material. It’s applied to form the lower layers of the roofing carpet. Material complies with Technical Specifications 5774-021-00287823-2013.

It’s the uncovered rolled material, made by means of impregnating the roofing paper (article 350) with oil bitumen. It’s the lining material. It’s applied to form the lower layers of the roofing carpet. Material complies with Technical Specifications 5774-021-00287823-2013.

Construction petroleum bitumen is produced in accordance with the requirements of GOST 6617-76 "Construction petroleum bitumen", technical regulations approved in accordance with the established procedure.

Construction petroleum bitumen is packed into four-layer paper bags with silicone coating, with net weight 40 ± 0,5 kg.

Range of manufactured articles: BN 70/30, BN 90/10

Warranty storage period for construction petroleum bitumen is 12 months.

| Name of the Parameter | BN 70/30 | BN 90/10 |

| Depth of penetration of the needle at 25 ° C; 0.1 mm | 21-40 | 5-20 |

| Melting point, °C, not lower than | 70-80 | 90-105 |

| Extensibility at 25°C, at least | 3,0 | 1,0 |

| Flash point, °C, not lower than | 240 | 240 |

| Quantity of bags on the pallet | 24 | 24 |

| Weight, kg / bag | 40 | 40 |

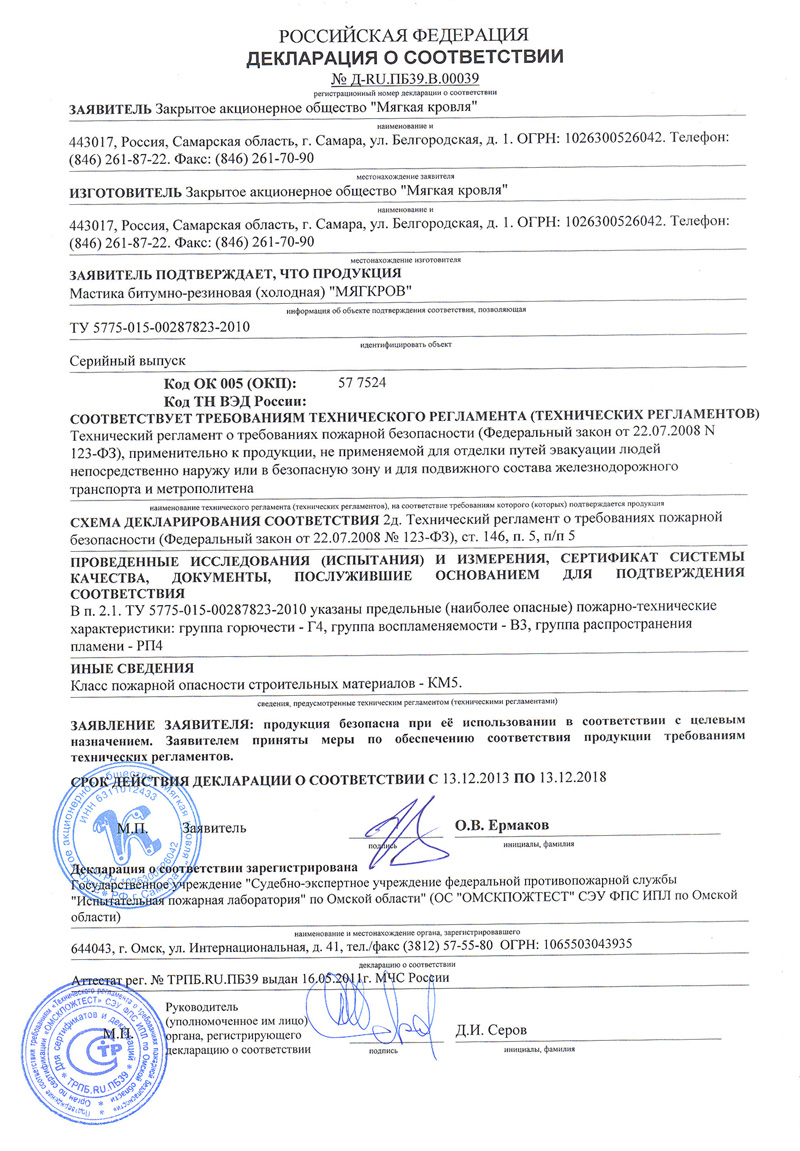

Bitumen-rubber (cold) mastic is used for repairing the roofs, waterproofing of building facilities, adhesion of the rolled roofing materials. It does not require any heating before application. It is packed in metal hermetically sealed containers (buckets). It’s the homogeneous viscous-liquid mass consisting of organic binding agent (construction petroleum bitumen), filler (rubber crumb), solvents, plasticizer. Material complies with Technical Specifications 5775-015-00287823-2010.

Range of manufactured articles: MBR-X-65, MBR-X-75, MBR-X-90, MBR-X-100

Warranty storage period for bitumen-rubber (cold) mastics is 12 months as from the date of production.

| Name of the Parameter | MBR-X-65 | MBR-X-75 | MBR-X-90 | MBR-X-100 |

| Conditional strength, MPA (kgs/cm²), not less than | 0,2(2,0) | 0,2(2,0) | 0,2(2,0) | 0,2(2,0) |

| Relative elongation at break, %, not less than | 100 | 100 | 100 | 100 |

| Strength of adhesion to the base, MPA (kgs/cm²), not less than | 0,1(1,0) | 0,1(1,0) | 0,1(1,0) | 0,1(1,0) |

| Water absorption for 24 hours, % by weight, no more than | 2 | 2 | 2 | 2 |

| Flexibility on bar with a rounding 5,0 ± 0,2 mm, at temperature, °С, not higher | -15 | -15 | -5 | -5 |

| Melting point, °С, not lower than | 65 | 75 | 90 | 100 |

| Waterproofing when tested for at least for 72 hours, under the pressure not less than 0.001 MPa (0.01 kgs/cm²) | Sample does not show any signs of water penetration | |||

| Quantity of bucket on the pallet | 36 | |||

| Weight, kg/bucket | 18 | |||

It is used for construction of rolled roofs, mastic roofs with glass materials reinforced. Mastic consists of bitumen binding agent, filler (talc-magnesite) and technological additives. It´s applied in hot condition.

Produced in accordance with the GOST 2889-80 "Bitumen hot roof mastic. Technical Specifications", technological regulations approved in accordance with the established procedure.

It is packed in paper bags with anti-adhesive interlayer by 40 kg of net weight each.

Range of manufactured articles: MBK-G-55, MBK-G-65, MBK-G-75, MBK-G-85, MBK-G-100

Warranty storage period for bitumen hot roof mastic is 12 months as from the date of production.

| Name of the Parameter | MBK-G-55 | MBK-G-65 | MBK-G-75 | MBK-G-85 | MBK-G-100 |

| Heat resistance within 5 hours, ºС, not less than | 55 | 65 | 75 | 85 | 100 |

| Melting point, °С, not lower than | 55-60 | 68-72 | 78-82 | 88-92 | 105-110 |

| Flexibility at temperature of 18 ± 2° Con a rod with adiameter, mm | 10 | 15 | 20 | 30 | 40 |

| Water content | 25-30 | 25-30 | 25-30 | 25-30 | 25-39 |

| Filler content, % by weight | Traces | ||||

| Number of bags on a pallet | 24 | ||||

| Weight, kg /bag | 40 | ||||

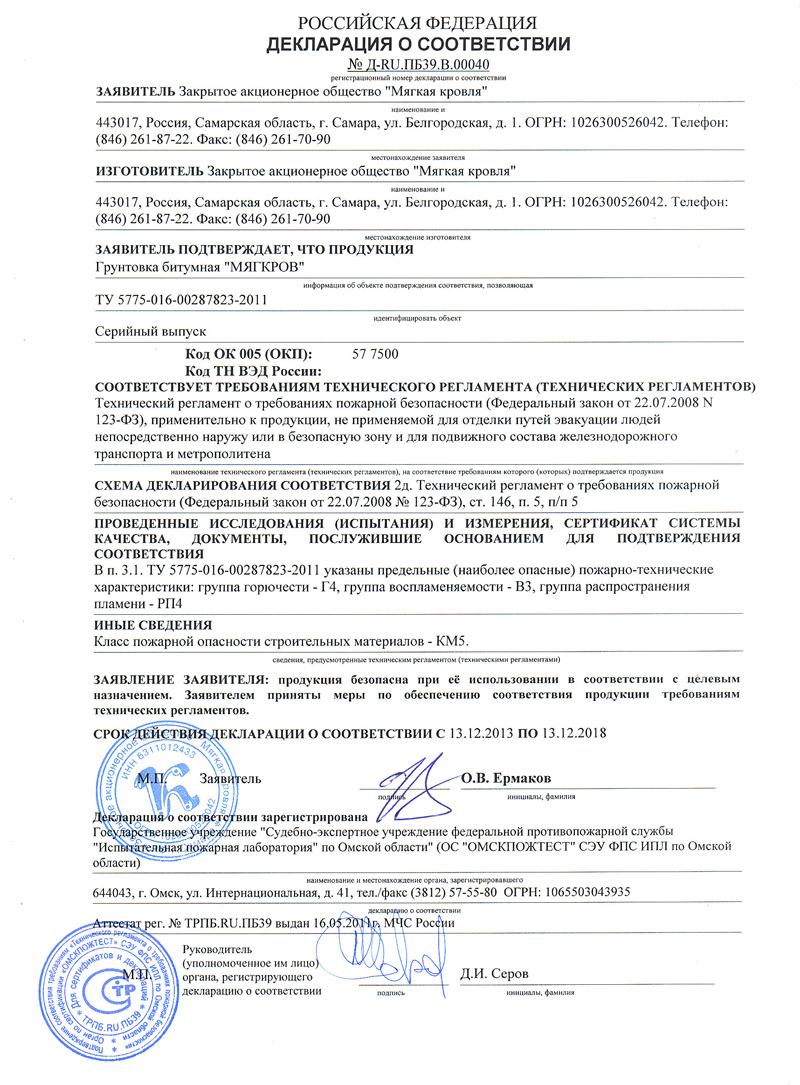

Primer is designed for preparation (priming) of any concrete base, sand cement screeds, surfaces made of reinforced concrete, brick, concrete and other porous, rough and dusty surface, in order to increase the adhesion of the base to the melting materials before laying roofing and waterproof materials. It also can be applied for the temporary waterproofing of building facilities and protection from corrosion; for patching any building facilities, concrete blocks, columns that contact with the ground.

Primer is a solution of petroleum bitumen with a softening point of at least 70°C in organic solvents.

Produced in accordance with the Technical Specifications 5775-016-00287823-2011.

Ready to use. It´s packed in hermetically sealed containers (buckets).

Warranty storage period for primer «Мyagkrov» is 12 months as from the date of production.

| Name of the Parameter | Values |

| Mass fraction of volatile substances, % | 45-60 |

| Drying time, hours, no more than | 12 |

| Number of buckets on a pallet | 36 |

| Weight, kg/bucket | 17 |

Articles to be applied: FPS-8-R-A, FPS-20-R-A, FPS-23-R-A, FPS-25-R-A, FPS-35-R-A, FPS-35ЕТ-R-A, FPS-15-T-B, FPS-25-T-B, FPS-35-T-B

Slabs made of foam polystyrene are designed for the loaded thermal insulation of roofs. The article FPS-8-R-A is used for the insulation of roofs, attics, attic spaces, slabs that do not undergo mechanical loads.

Foam polystyrene is the eco-friendly and moisture resistant material; it has low weight and is convenient for installation.

Articles to be applied: FPS-8-R-A, FPS-10-R-A, FPS-12-R-A, FPS-13ЕТ-R-A, FPS-13-R-A, FPS-14ЕТ-R-A, FPS-16Ф-R-A

Thermal insulation slabs are designed for making the unloaded thermal insulation in the medium layer of three-layered protective structures. The slabs of such articles as ППС16Ф-Р-А are used for insulation of vertical protective structures, along with the facade heat-insulating composite systems with external plaster layers.

The slabs with the article FPS-8-R-A are used for providing the thermal insulation of wagons, vans and containers.

Articles to be applied: FPS-20-R-A, FPS-23-R-A, FPS-25-R-A, FPS-35-R-A, FPS-35ЕТ-R-A, FPS-15-T-B, FPS-25-T-B, FPS-35-T-B

Foam polystyrene slabs are designed for making the thermal insulation of surfaces exposed to significant loads (floors, foundations, ground levels and ground floors of the buildings, garages, car parkings, swimming pools, cold rooms, artificial skating-rinks, etc.) during their further operation.

Foam polystyrene is the eco-friendly and moisture resistant material; it doesn’t attract rodents.

The slabs of such articles as FPS-25-T-B and FPS35-T-B are made in beige color and their quality features are not inferior to extruded foam polystyrene.

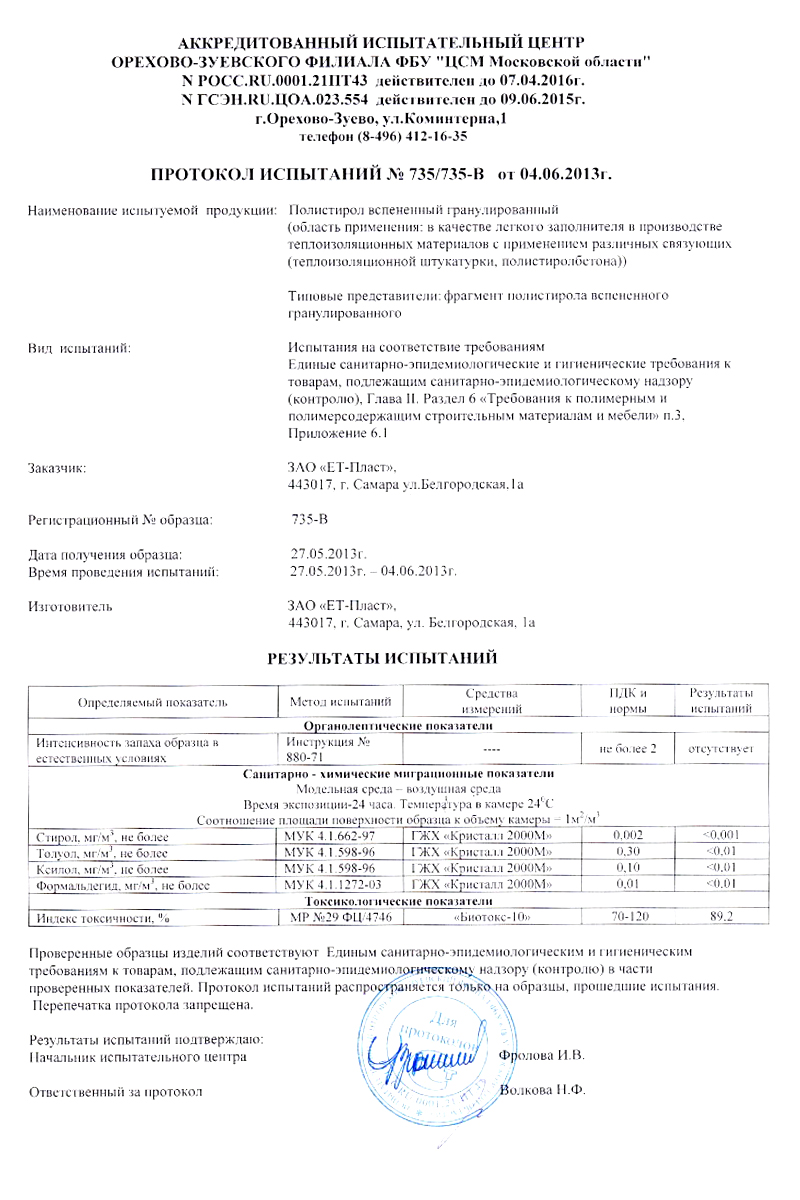

Granulated expandable polystyrene is produced in accordance with Technical Specifications 2214-004-48124154-2005. Expandable polystyrene bead looks like white spherical-shaped granules, there are many closed cells filled with air inside of them. Expandable granules could be used as light filling agents for the production of the heat-insulating materials, along with the application of various binders (heat-insulating plaster, polystyrene concrete). Granules couls be used as filling agents for the production of the Padded Furniture. They are packed in polyethylene bags from 1m³ to 3m³ each.ç

Heat-insulating wall blocks are designed to form the single-layer bearing masonry with a thickness of 300 mm for buildings with increased requirements of thermal resistance and heat accumulation by the wall while keeping small thickness of the outer masonry that allowas maximum use of the internal space.

The masonry made of heat-insulating blocks can be used for the construction of cottages, villas, apartment blocks and industrial buildings (production shops, enterprises, heated warehouses and garages, car service stations, gas stations, shops), for buildings of civil facilities (schools, gyms, hotels, ponds, waste treatment plants, etc.) with a maximum height up to 4-5 floors.

Cardboard box is made paper and cardboard waste in accordance with the requirements of GOST 7933-89 "Cardboard for consumer packaging. General Technical Specifications" and in accordance with the normative and technical documentation for a specific type of products.

Cardboard box is designed for manufacturing consumer and group containers without printing. It is used as lining material and packaging of industrial goods, furniture, as a basis for the production of other types of cardboard, cardboard separating sheets, as the thermal insulating material in railway containers and wagons.

It is produced in rolls (1000 ± 3 mm, 1050 ± 3 mm) and sheets (1050*800 mm, 1050*1200 mm, 1050*1600 mm).

Box cardboard can be produced in such articles:

200, 250, 300, 350, 400.

| Name of the Parameter | GOST 7933-89 | 200 | 250 | 300 | 350 | 400 |

| Weight of cardboard area of 1 m², g | 200-400 | 200 ± 15 | 250 ± 15 | 300 ± 15 | 350 ± 20 | 400 ± 20 |

| Thickness, mm | 0,30-0,80 | 0,32±0,02 | 0,42±0,02 | 0,50±0,03 | 0,60±0,04 | 0,740±0,04 |

| Stiffness in static transverse bending, N * cm | 0,20-2,50 | 0,40-0,50 | 0,60-0,70 | 0,80-0,90 | 1,10-1,20 | 1,30-1,40 |

| Humidity, % | 5-12 | 8,0 | 8,0 | 10,0 | 10,0 | 10,0 |

Flat bonded container cardboard is produced by adhesive bonding of several layers of cardboard.

It is used as a material for productions of inserts which provide tightness between flat metal surfaces; as coverings for books; as a lining material between pallets; in textile industry (material for making patterns, frames for hats, bags); in footwear industry (inserts into the heel and toe for shaping the shoes); for production of cardboard separating sheets; as thermal insulation in railway wagons; as a basis for gypsum plasterboard.

Flat bonded container cardboard is produces in sheets:

| Name of the Parameter | ||

| Weight of cardboard area of 1 m², g | 1000±100 | 1250±100 |

| Thickness, mm, not less than | 1,4 | 1,8 |

| Bursting strength, MPa, not less than | 0,75 | |

| Resistance to separation, N, not less than | 48 | |

| Humidity, % | 12(+2;-4) | |

Every year we take part in interregional and international construction exhibitions. Our materials have been awarded numerous diplomas and prizes in terms of quality, and the factory has been appreciated for achieving high efficiency and its competitive activities. Herewith we will present only a part of our special-significant awards.

Reward to the Factory “Soft Roof” (Myagkaya Krovlya) at the Regional Forum "Line of Success" - Cup of Merits

Diploma of the winner of the XVII All-Russian Competition for the best enterprise of construction materials and construction industry in 2012

Address: 443017, Russian Federation, Samara, 1 Belgorodskaya St.

Phone: +7 (846) 21-21-338, +7 (846) 21-21-335

E-mail: krovlya@mkrovlya.ru